Rapid Tooling

|

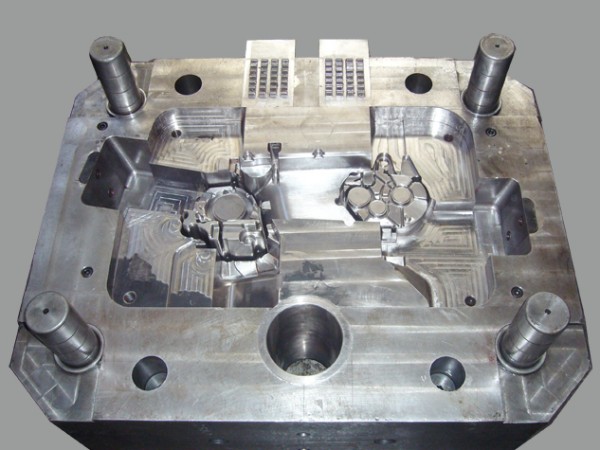

Rapid tooling:

sometimes known as prototype tooling or bridge tooling, is a fast and cost-efficient way to carry out low-volume injection molding for a variety of types of plastic parts. Once the aluminum or steel mold has been created with the rapid tooling process, it can be utilized as part of a molding process to create multiple copies of a part. Rapid tooling is therefore used to create moldings for rapid prototyping needs in a shortened time frame, or to bridge the gap before high-volume production. |

|

At GT-prototype, we combine our experience, engineering capabilities and advanced technology to produce high-quality rapid tooling solutions for prototypes and short production runs. Our team works directly with each customer to ensure that we create the perfect solution. Our experience speaks for itself. The team at is well-equipped to handle your rapid tooling and mass production mold making requirements. If you are ready to start mass production, learn more out our injection molding services.

|

Benefits of Rapid Tooling

Rapid production tooling gives a number of advantages over other methods of prototype production:

|

|

|

Aluminum Mold:

Aluminum mold tooling provides a cost-effective way to produce molded parts. Since they are easy to cut and Aluminum evenly dissipates heat, which provides dimensional stability in tooling. This significantly reduces deformation and produces less waste during the production process. aluminum molds can reduce tooling costs by 16–30% compared to other mold materials and reduce cycle times by up to 35%. This translates to a faster turnaround for our customers.

It is important to note that aluminum is not as strong as steel, so it has a shorter life cycle and is less useful in high-volume processes. |

|

|

Steel Mold:

Steel is a sturdy, solid, high-quality tooling material, though it is not suitable for all applications. Steel molds have a longer life cycle than aluminum and are therefore ideal for high-volume production.Steel can also be used to produce molds from engineering-grade plastics that are resistant to abrasion and corrosion.

Though it features multiple benefits, steel is a more expensive tooling material than aluminum and requires more turnaround time to produce molds and prototypes. |

|

Parts of the product:

|

|

|

|

|

|