|

During the manufacturing process, once a product is functionally complete, the next stage is surface finishing. surface finishing in fabrication is very important to ensure a durable and beautiful product. However, when dealing with aluminum products, a highly reputed method is anodizing. If you are someone into this method, you might want to know the cost to anodize aluminum products.

Aluminum anodization is an electrochemical process that transforms the aluminum surface into a decorative, durable, corrosion-resistant and wear-resistant oxide layer. The alumina is not applied to the surface like coating or electroplating, but is completely integrated with the underlying aluminum substrate. |

|

Benefits of Anodizing Aluminum Parts

Among the many surface finishing techniques used on different products, especially aluminum products, Anodizing has better advantages. What then makes anodizing aluminum better than other techniques such as painting? Below are a few reasons why you should choose the technique.

Durability

Anodizing process leads to the formation of oxides of aluminum which is known for its hard property. The oxides are harder than the base metal, and on anodizing a part, we increase the surface area of its oxide layer. So, the surface of the part becomes much harder. With Type 3 anodizing, it can reach some metal cutting tool steels.

Resistance to Chemical Reactions

On coating, the aluminum surface becomes resistant to chemical reactions. This is because the coating stabilizes the surface leading to an unreactive property with chemicals. It does not matter whether it is at a high temperature, the oxide will still stay unreactive stand strong.

Paint Retention

Anodizing aluminum parts ensures that they do not peel off. This is because the pore retains the anodizing color. Therefore, normal mechanical actions such as peeling cannot lead to scratching off of color.

Eco-friendly

Anodization is an eco-friendly process because its by-products are non-toxic. This makes them stand out amidst other techniques used in the industry.

Adhesive Options

The anodized surface can contain adhesives such that the different aluminum parts which allow you to glue them together.

Aesthetics

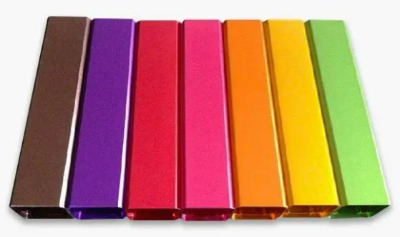

Anodization is a good surface finishing technique for aluminum parts when thinking of aesthetics. It offers a beautiful and unique finish that complements wherever it is used.

|

|

Electrolytic colored oxide film and hard oxide film have been widely used in our lives, so today we will focus on analyzing the factors that affect the cost, coloring and quality of anodized aluminum parts.

Factors Affecting the Anodizing Aluminum Part Cost

Regarding the cost of anodized aluminum parts, although it depends on different requirements, there are three key factors that affect the cost of anodized aluminum parts. The cost of anodized aluminum mainly depends on the thickness of the coating, the size and shape of the parts, and the additional services required.

Coating Thickness

If the type of coating does not require a specific thickness, it is considered a “basic” coating and has the lowest price.

Controlling the precise coating thickness will affect the cost. If the coating thickness specification includes upper and lower limits, the narrower the range, the higher the cost. For example, the price of +/-.001″ is cheaper than the stricter range of +/-.0001″. The maximum coating thickness may cost more because they require longer production times.

Dimension and Components of Anodized Aluminium

The chosen material dimension is a factor that plays a major role in the cost to anodize aluminum parts. The higher the dimension, the greater the surface area, and the higher the materials and facilities needed to make the process successful. Also, an increase in the number of components means an increase in labor and time. These two translate directly to anodized aluminum price.

Racking

The rack is critical to quality. Aluminum or commercial pure titanium racks will be used to make electrical contacts. If the job does not specify shelf requirements, the manufacturer will use the most cost-effective method to obtain the highest yield. Special shelf requirements may limit the number of parts processed at one time, and the cost of each part may rise.

The number of parts anodized at one time is affected by power supply limitations. Anodizing is performed at 15 or 30 amperes per square foot (ASF). Therefore, the maximum surface area can be processed in each run.

Additional Services

Customers usually need other processes to increase the anodizing process. These services will increase labor and time when parts require simple or complex covering or punching. These services add value, but also increase the total cost of anodized aluminum.

As a customer, if you require additional processes to make the process more efficient, you have to pay more. It is also the same when you are targeting the aesthetics of such products. Planning to plug or mask holes means additional service and additional price.

Want to get anodized aluminum parts at a great price? GT is for you.

GT is a professional brush anodizing fabrication service providers in China, provide high quality metal surface finishing services.