|

The benefits of 5 axis machining may not be obvious to non-experts. After all, your CNC machined parts are three-dimensional, not five-dimensional, right? Intuitively, you might think that a 3 axis CNC machine should be capable of handling most machining jobs.

In actual fact, 5 axis machining is today the most viable solution for all kinds of machining projects — not just highly complex ones that demand greater tool reach.

For newcomers to CNC technology, 5 axis machining is a form of CNC machining in which the workpiece (the part in progress) or the cutting tool can move along five axes. In many cases, it’s a combination of the two — for example, the cutting tool moves along three axes (up and down, back and forth, side to side) while the table holding the workpiece moves along two (rocking back and forth, rocking side to side).

|

|

|

What is 5-Axis Machining? 5-Axis machining refers to using a CNC machine to manipulate a component along five different axes at the same time. For industries that require complex components to be intricately manufactured (such as Aerospace), 5-axis machining offers a whole host of benefits.

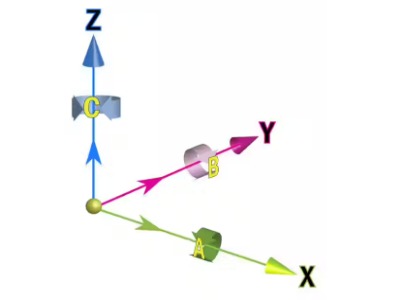

So what are the five axes that we are referring to? Sticking to our theme of aerospace, let’s picture a stunt plane in mid flight. The plane’s position in three-dimension space can be described by using three letters, X, Y and Z. But we all know about height, depth and width, so where do the other two fit in?

The other two axes refer to the stunt plane’s orientation rather than its position. Our fourth axis (labelled as A) describes the horizontal rotation of the plane, also visualised as a rotation around axis Z, height. The fifth axis is the plane’s rotation around axis Y, or ‘roll’.

But then of course, what about the rotation around axis X? While using this method of defining a multitude of axes does indeed offer us six variables in which to work with, adding the sixth rarely offers any added benefits when it comes to component production. |

|

5 axis machining offers benefits like increased productivity, longer tool life, and a much wider range of possible geometries.

Whether you’re a customer looking to order machined parts from a manufacturer like GT, or if you’re running your own machine shop and think about investing in 5 axis milling capabilities, this article provides five key reasons why you should start using 5 axis machining today.

1. Single setups for greater productivity

One of the most time-consuming aspects of 3-axis machining is setting up a workpiece multiple times because the part needs reorienting. This is necessary if a part needs to be machined on all or several sides since the cutting tool remains at a fixed angle.

For these 3-axis jobs, a machinist must be physically present to reorient the part when machining on one side is complete, and this human requirement can be a serious bottleneck to productivity.

5-axis machining greatly reduces the need for multiple setups, since the movement of the table or spindle allows the cutting tool to access the workpiece from different angles without removing it from the machine and setting it up again.

Reducing the number of setups can be hugely beneficial for productivity. The machine can run continuously with minimal human labor, meaning more parts can be built in less time.

2. Shorter cutting tools and improved quality

A serious disadvantage of 3 axis machining is the need for long cutting tools due to restricted movement.

5-axis machining allows the use of shorter cutting tools since the machine allows the tool to get closer to the workpiece at a better angle. This has important knock-on effects, such as allowing for faster cutting speeds without risking damage to the cutting tool or increasing undesirable tool chatter, which affects the quality of the part and the ability of the machine to hit tight tolerances.

Use of shorter cutting tools benefits both the machine shop and the customer. The machine shop gets a longer life expectancy for its cutting tools, while the customer receives parts with better quality and surface finish, and can demand tighter tolerances on fine features.

3. Better for complex parts

It almost goes without saying that 5 axis milling and machining can be used to produce more complex machined parts than would be possible with only 3 axes.

Additional movement of the table and/or spindle provides the cutting tool with comprehensive access to the workpiece, allowing for unique tool path operations and complex machined shapes.

This added complexity means 5 axis CNC machines can be used in place of other, more costly manufacturing methods like casting.

5 axis milling is now widely used in the aerospace industry, where unusual geometries are required for reasons of lightweight or aerodynamics.

4. Cuts mold cavities with ease and precision

CNC machining is often used to make molds for injection molding, especially in the area of rapid tooling where low-cost aluminum is generally used to make the molds.

5 axis machining results in higher-quality molds since its added degrees of movement make it better equipped to handle deep cavities when compared to 3 axis machining. The added accuracy of 5-axis also results in a better surface finish on the mold, reducing the need for comprehensive polishing.

Simultaneous 5 axis machining is also ideal for tall core molds and deep pocket molds.

5. Flawless curved parts

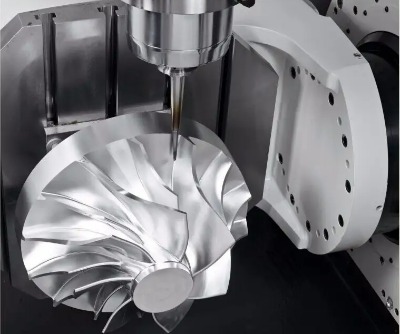

Curved parts like fins and turbine blades are not suited to 3 axis machining — and even less suited to alternative processes like FDM 3D printing, which is notorious for its step-like surface finish.

With simultaneous 5 axis machining, on the other hand, it is possible to machine smooth and consistent curves onto the workpiece, or to machine details onto an already curved workpiece.

By rotating the table or spindle as the tool cuts the workpiece, it is possible to maintain a consistent cutting angle even along a curved edge.

GT 5-Axis CNC machining Services

Have you been looking for the best company that can offer you an excellent machining services including 5-Axis CNC machining? Now you can relax because your search stops here.

GT is a professional 5-Axis CNC machining providers in China, provide high quality 5-Axis CNC machining services.

At gt, we offer quality CNC machining at reasonable prices. With us, you can save 32% of your budget. We know that you want quality finishing for your parts production without breaking a bank to get it; that is why our quality service is affordable.

We have more than 100 sets of 3, 4, and 5-axis CNC machines and a wide range of auxiliaries in China. Therefore, you can relax because we are capable of handling your project. With us it doesn’t matter what tolerance, material, or surface finish is needed for your metal parts. We always deliver. We also know how much you value time; thus, we deliver within the promised lead time.

Also, you don’t have to come all the way down to our firm to get your job done. Just contact us through email, and we’ll attend to your needs. You can also upload your CAD file to get a quotation.

Advantage of GT-PROTO 5-Axis CNC machining services