Aerospace engine parts are high quality requirements, GT combined with CNC machining and rapid prototyping to perfectly achieve customer needs

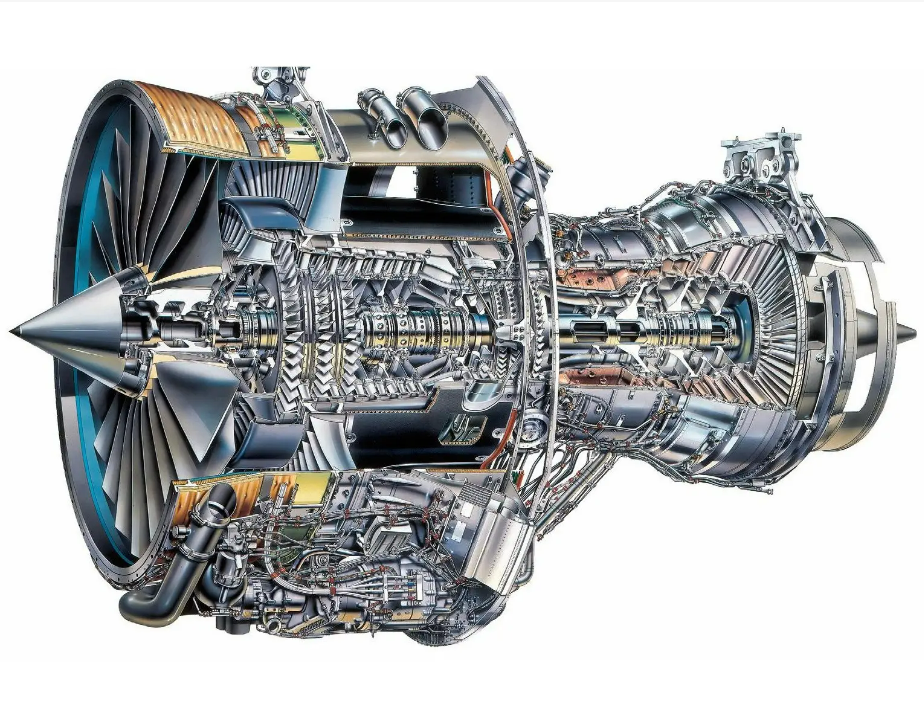

Rapid Prototyping Molding for Aerospace engine

|

Aerospace engine is the device that provides power for automobile and the heart of automobile, which determines the power, economy, stability and environmental protection of automobile. According to different power sources, automobile engines can be divided into diesel engine, gasoline engine, electric vehicle motor and hybrid power, etc. |

|

Specifications of moulding for Aerospace engine

| Description: | Aerospace engine |

| Part Material: | Aluminum Titanium Magnesium Stainless steel |

| Surface Treatment: | Sandblasted |

| Manufacturing process: | CNC machining, Injection molding, Surface Finishing |

| Delivery cycle: | Four weeks |

Fabrication:

|

Automobile engine structure (main components of the engine): composed of two mechanisms and five systems. Body and crank connecting rod mechanism Valve train Fuel supply system Cooling system lubrication system Starting system Ignition system |

|

|

The body: The shell is made of aluminum through 5-axis CNC machining, and then sand blast to make the surface smooth. |

|

|

|

The shell: |

|

Advantage of GT-PROTO CNC machining

Customer Reviews

Leroy Somer,the one of the top ten engine manufacturers. The company was founded in France in 1919. The company sells 2000 kinds of products, including AC motor, motor reducer, wound motor, soft starter and other parts. David, their engineer, he said: From design to prototype production, and then to mass production, the generator has high requirements for the manufacturer's programming machine and manual processing. Manufacturers not only need experienced programming, but also high-precision five -axis CNC machines, as well as strict requirements for the precision of post-processing. We are very grateful to GT for providing us with such wonderful parts and are proud of them.

Tags :