GT’ combined injection molding prototyping services and production solution saves months of product development and 20% of the production cost for Waqu biology.

Rapid Prototyping Molding for Nucleic Acid Detector

|

Nucleic acid protein detector, also known as ultraviolet detector, is a kind of ultraviolet detector in liquid chromatography experiment, with the upper chromatographic column, constant current pump, automatic part collector and liquid chromatography data workstation, etc., formed a complete set of separation chromatography system. Waqu Biology is a professional development and production of nucleic acid detector start-up company, reduced the time to market for its Nucleic acid detector by several months using GT design analysis, prototyping. |

|

Specifications of moulding for Nucleic Acid Detector

| Description: | Nucleic Acid Detector Mold |

| Part Material: | ABS ALUMINUM 6061 PC PAAM |

| Surface Treatment: | Sandblasted |

| Manufacturing process: | Sheet metal manufacturing, CNC machining, Injection molding |

| Delivery cycle: | Three weeks |

| Mold Characteristics: | excellent cooling system design |

| Short cycle time |

Communication Advice

The client plans to use black ABS as a support material for the instrument because it is a tough plastic with a natural good surface finish. Black ABS is also a good electrical insulator making it an ideal choice for the application. However, considering the force problem of ABS material oscillating continuously at high temperature for a long time.

GT gives another suggestion:

Fabrication:

We combine sheet metal manufacturing, CNC machining, injection molding process to manufacture the entire instrument frame structure.

|

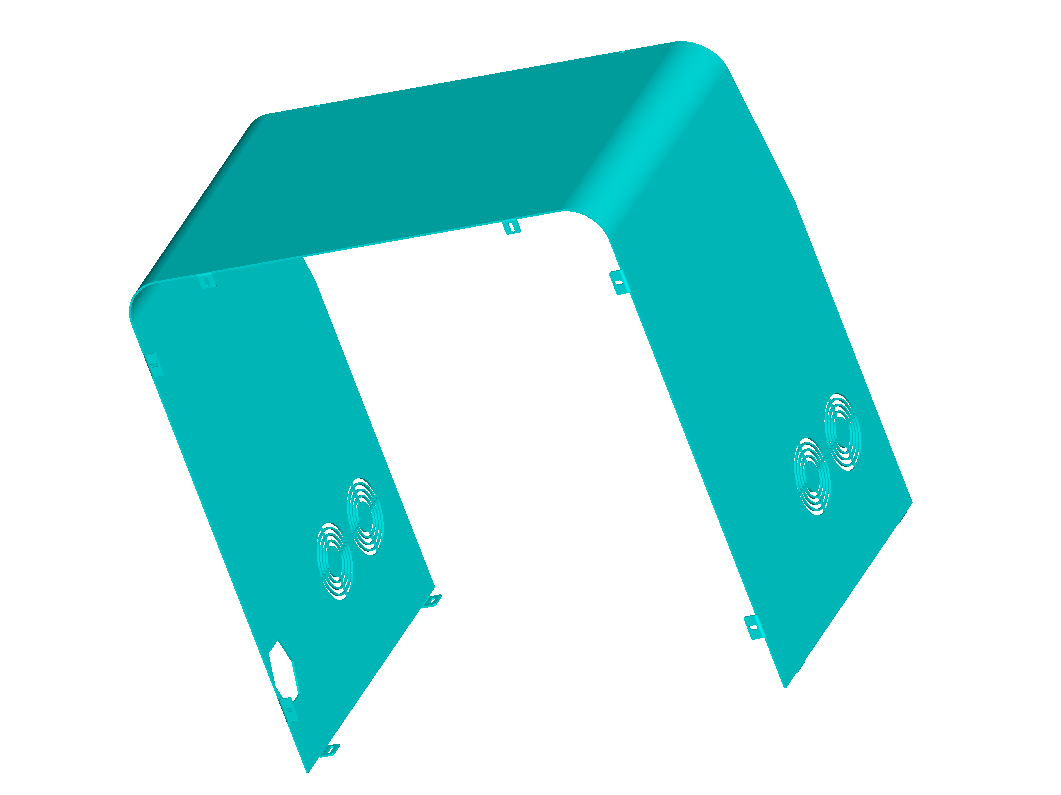

The body: The shell is processed by sheet metal and then sandblasted. |

|

|

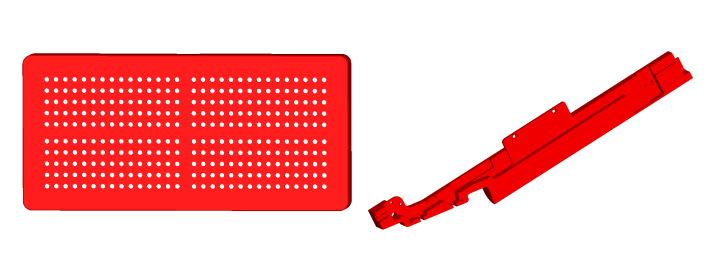

Support frame/box body: |

|

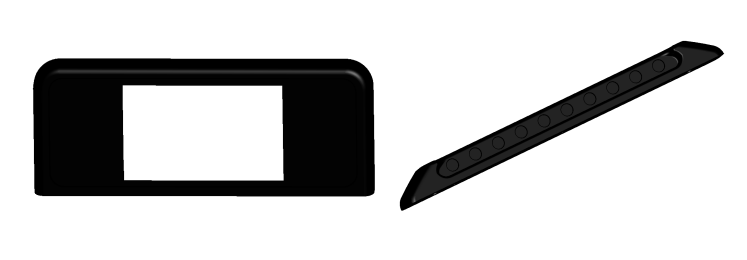

Panel/handle: |

|

Advantage of GT-PROTO Injection Mould

Customer Reviews

Storey Yang, senior engineering buyer, commented: "The new product is highly specialised equipment that needed a lot of development and testing before production. The fact that GT could provide design feedback within a couple of hours after we uploaded our CAD into its design for manufacturability analysis software, rapid prototyping of the parts, and a low volume injection moulding solution that keeps the cost per part down was invaluable. This joined up thinking makes a lot of sense for specialist manufacturers who need low to medium volumes of parts like us. It also meant that that the prototype designs and material had the final production process in mind."

Tags :