GT’ combined CNC machining, injection molding process Ensure fast product delivery and save about 2 weeks time to market for customers

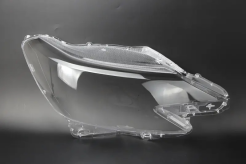

Rapid Prototyping Molding for Headlamp

|

Headlamp, also known as headlamp, its assembly is one of the important components to ensure the safe operation of the vehicle. It is installed on both sides of the vehicle head for the lighting of the road at night. The farther the headlamp is illuminated, the better the light distribution characteristics, and the higher the safety performance of the vehicle. |

|

Fabrication:

The headlamp is mainly composed of bulb, reflector and lens. The car's headlamp is the lighting device installed on both sides of the car's head for driving at night, which is used in conjunction with the car's high beam and low beam.

The main plastic materials for automobile lamps include PC, PP, ABS, PMMA and a few other plastic materials

We combine CNC machining, injection molding process to manufacture the entire instrument frame structure.

|

The Shell: The shell is made of PC board through CNC processing, and then vapor polish to achieve the effect of optical quality. |

|

|

Housing:

Most of the PP used in lamps are modified PP, accounting for about 30% of the plastic materials for lamps (weight ratio). |

Advantage of GT-PROTO CNC machining

Tags :